In X-ray fluorescence(XRF),energy-dispersive spectroscopy(EDS),and electron microscopy applications,detector peformance is fundamentally limited by temperature-sensitive noise mechanisms.

Leakage current and electronic noise increase rapidly with temperature.

Even a1℃temperature fluctuation can cause a significant rise in noise,leading to:

1.Degraded energy resolution

2.Peak broadening and overlap of adjacent elemental lines

3.Reduced peak-to-background ratio

4.Poor accuracy and repeatability in elemental identification

Precise and stable temperature control is therefore a prerequisite for high-resolution X-ray detection.

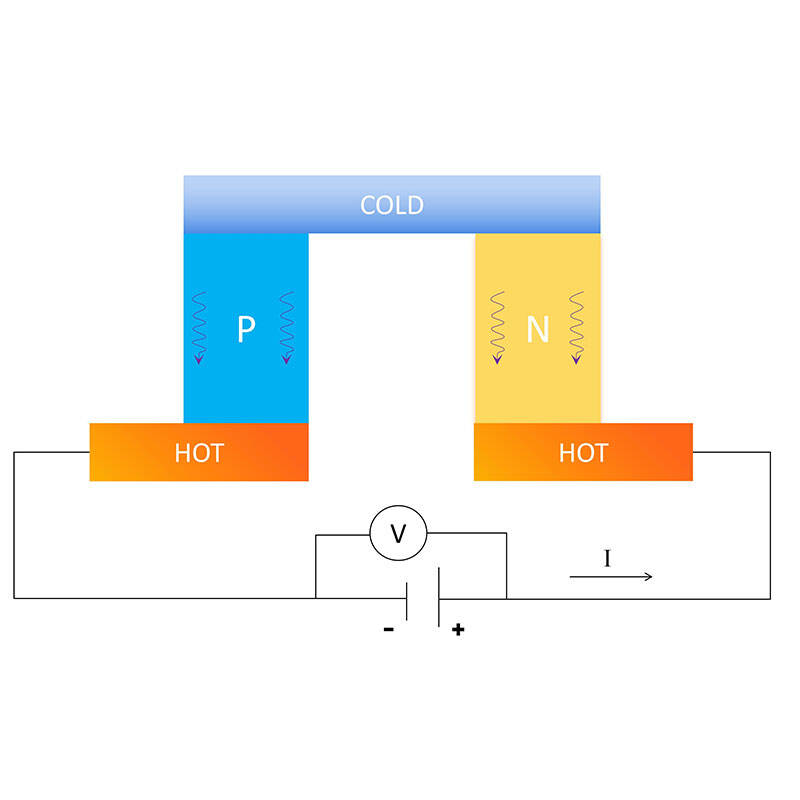

By actively cooling and stabilizing the detector at-20℃to-60℃,TEC cooling enables:

1.Energy resolution optimized to~125 [email protected] keV

2.Peak-to-background ratio improved by 3-5×

3.Lower detection limits reaching ppm level

4.Narrower spectral peaks and clearer elemental separation

5.Stable detector behavior during long measurement cycles

1.Solid-state design with no moving parts→high reliability and long lifetime

2.Zero vibration operation→no impact on spectral stability

3.Precise temperature control(±0.1℃typical)→consistent energy calibration

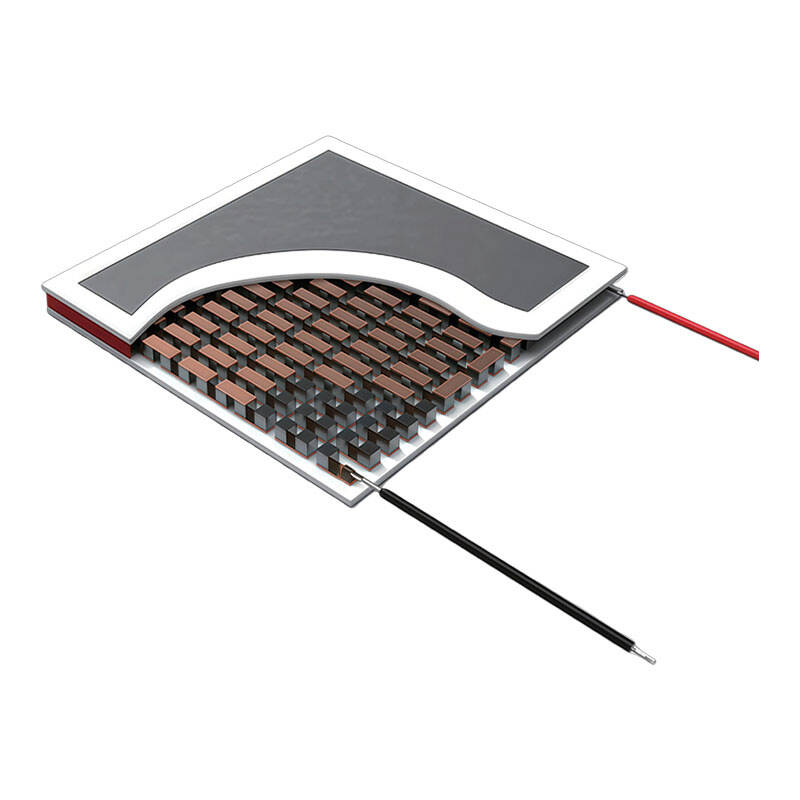

4.Compact and integrable→suitable for TO-8 and other miniature detector packages

5.Orientation-independent and maintenance-free→ideal for laboratory and field instruments

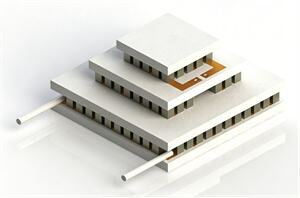

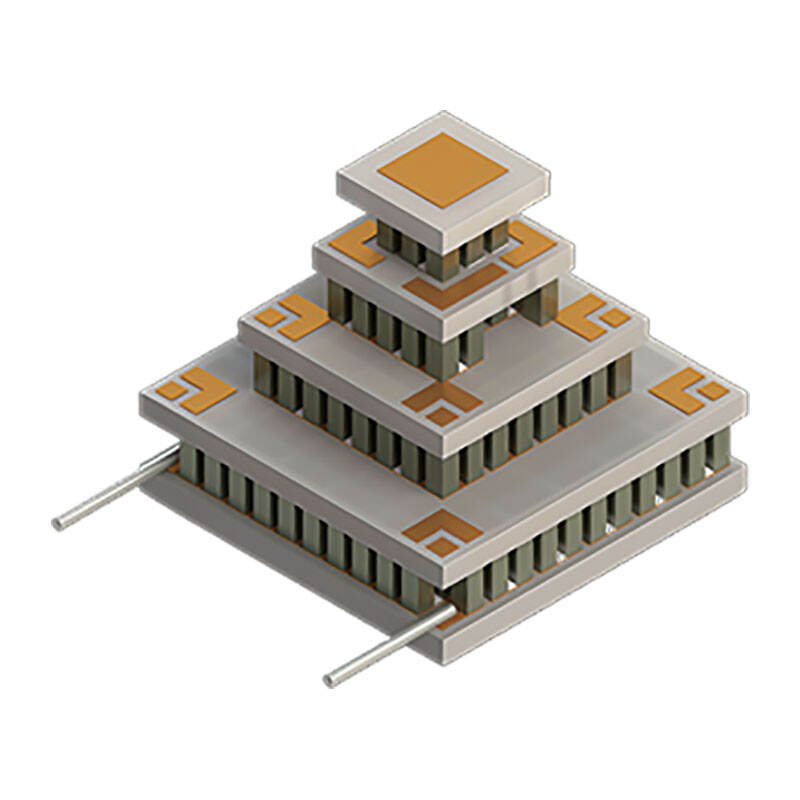

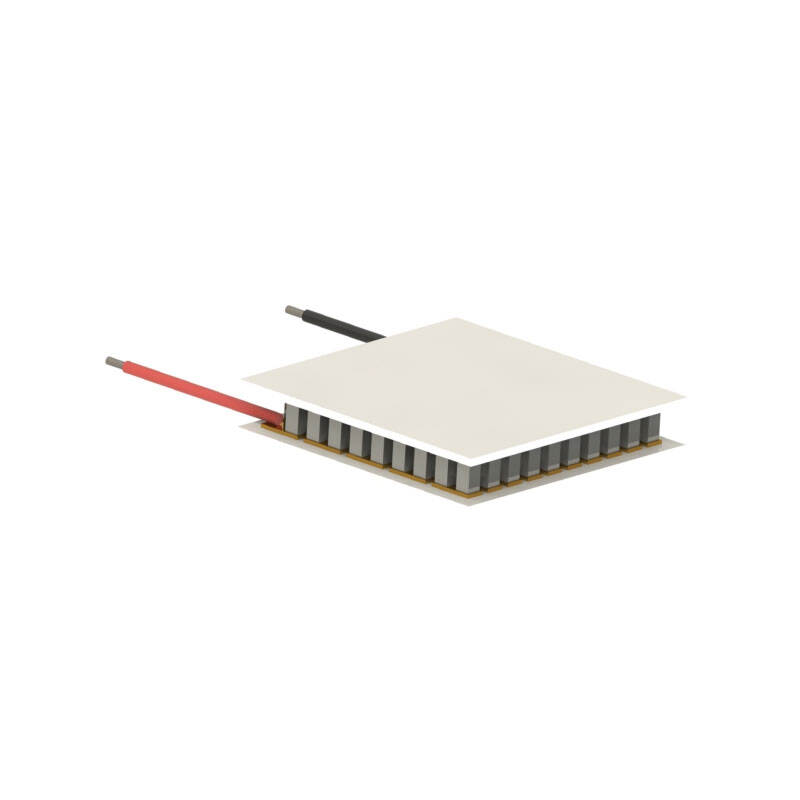

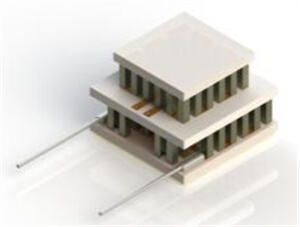

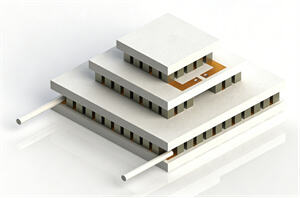

The following models represent typical multi-stage TEC models commonly used in X-ray detectors applications.They are provided for reference and comparison only,not as a complete product list.

| TEC model | Imax(A) | dTmax(®C) | Qcmax(W) | Umax(V) | ACR(ohm) | Top(mm) | Bottom(mm) | Height (mn |

| 2iTEC-039- 0450415 | 0.5 | 112 | 0.59 | 3.8 | 6.35 | 4.8x4.8 | 6.4x6.4 | 4.37 |

| Th=50℃& Vacuum | ||||||||

| TEC model | Imax(A) | dTmax(°C) | Qcmax(W) | Umax(V) | ACR(ohm) | Top(mm) | Bottom(mm) | Height(mm |

| 3iTEC-071-040210 | 0.55 | 115 | 0.4 | 5.8 | 9.05 | 2.6x2.6 | 6.2x6.2 | 5.3 |

| Th=27°℃&Vacuum | ||||||||

| TEC model | Imax(A) | dTmax(*C) | Qomax(W) | Umax(V) | ACR(ohm) | Top(mm) | Bottom(mm) | Height(mm |

| 3ITEC-070-040410M | 0.54 | 112.6 | 0.5 | 5.8 | 9.7 | 7.9x7.9 | 8x8 | 4.7 |

| Th=30°℃& Vacuum | ||||||||