PCR instruments require rapid and repeated temperature transitions to enable DNA denaturation,annealing,and extension.

This places extreme mechanical and thermal stress on TEC modules.

In conventional solder-based TEC structures,repeated heating and cooling cycles lead to:

1.Accumulation of therma stress inside the module

2.Fatigue and cracking at copper-ceramic interfaces

3.Degradation of electrical and thermal performance over time

4.Reduced lifetime and risk of premature module failure

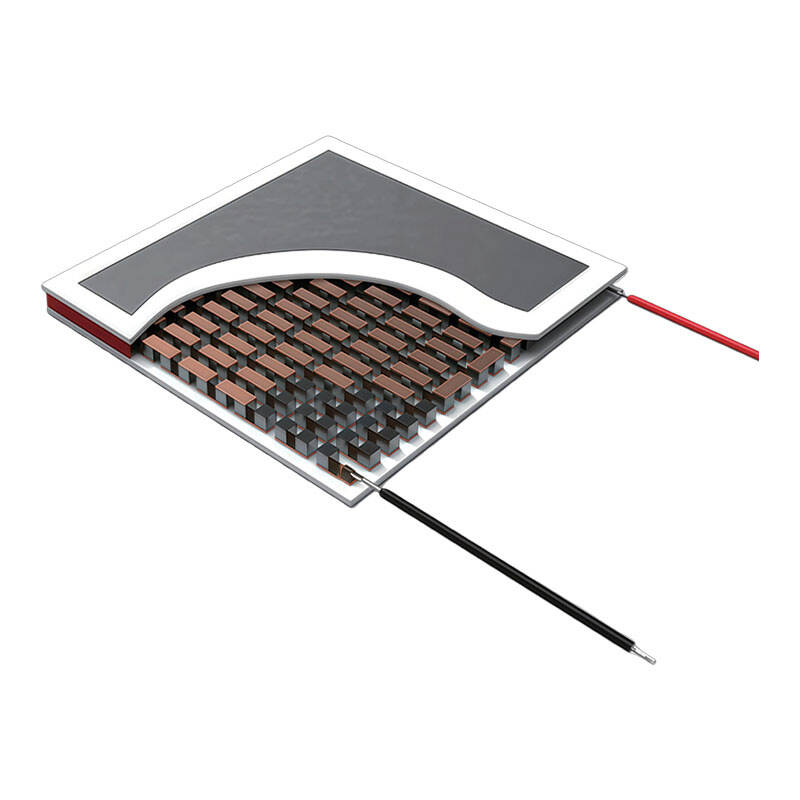

The TCR series TEC adopts a flexible adhesive layer between the copper conductor

and ceramic substrate,specifically optimized for high-cycle thermal applications.Key performance improvements include:

1.Effective stress relief during rapid heating and cooling

2.Reduced mechanical strain on P-N dice and interconnects

3.Thermal cycling endurance exceeding 800,000 cycles

4.Stable performance under continuous PCR operation

5.Improved consistency across long test runs

1.Flexible adhesive layer→mitigates thermal stress accumulation

2.Solid-state,vibration-free design→ideal for sensitive biochemical assays

3.High reliability under fast ramp rates→supports rapid PCR protocols

4.Long operational lifetime→reduces maintenance and replacement cost

5.Compatibility with compact PCR architectures→enables instrument miniaturization

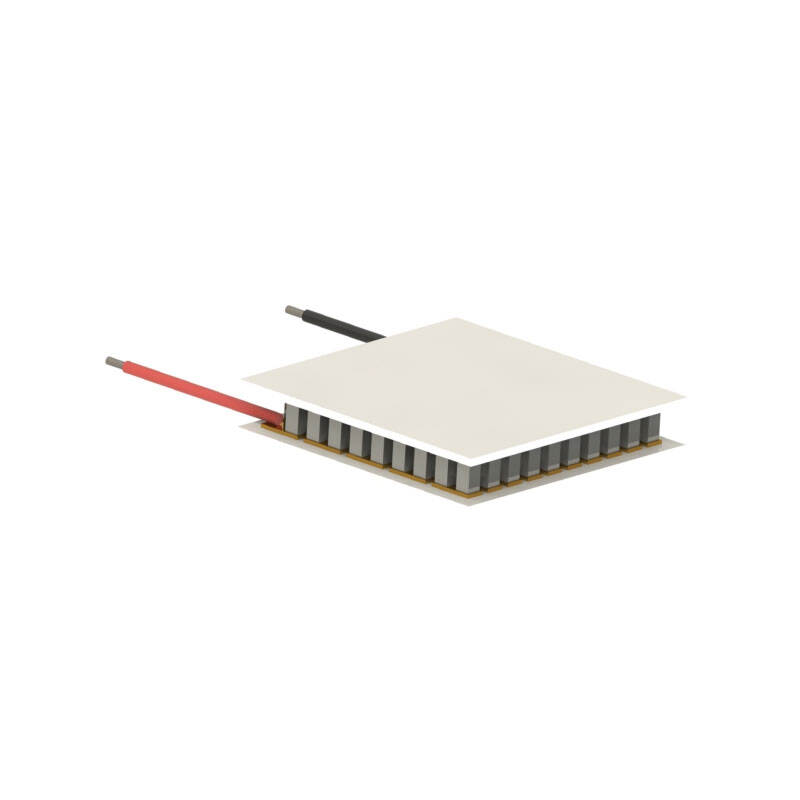

REPRESENTATIVE TEC MODELS FOR PCR SYSTEMS

The following models represent typicalTEC models commonly used in PCR systems applica-tions.They are provided for reference and comparison only,not as a complete product list.

| TEC model | Th=50℃ | Dimensions(mm) | |||||||

| I max (A) | Qmax(W) | V max(V) | ΔT max (° C) | N | A | B | C | D | |

| TCR-071020 | 2 | 11.2 | 9.1 | 78 | 71 | 20 | 20 | 20 | 4.80 |

| TEC model | Th=50℃ | Dimensions(mm) | |||||||

| I max (A) | Q max (W) | V max(V) | ΔT max(° C) | N | A | B | C | D | |

| TCR-152080 | 8 | 90 | 22.8 | 78 | 152 | 16.8 | 74.5 | 77 | 3.30 |