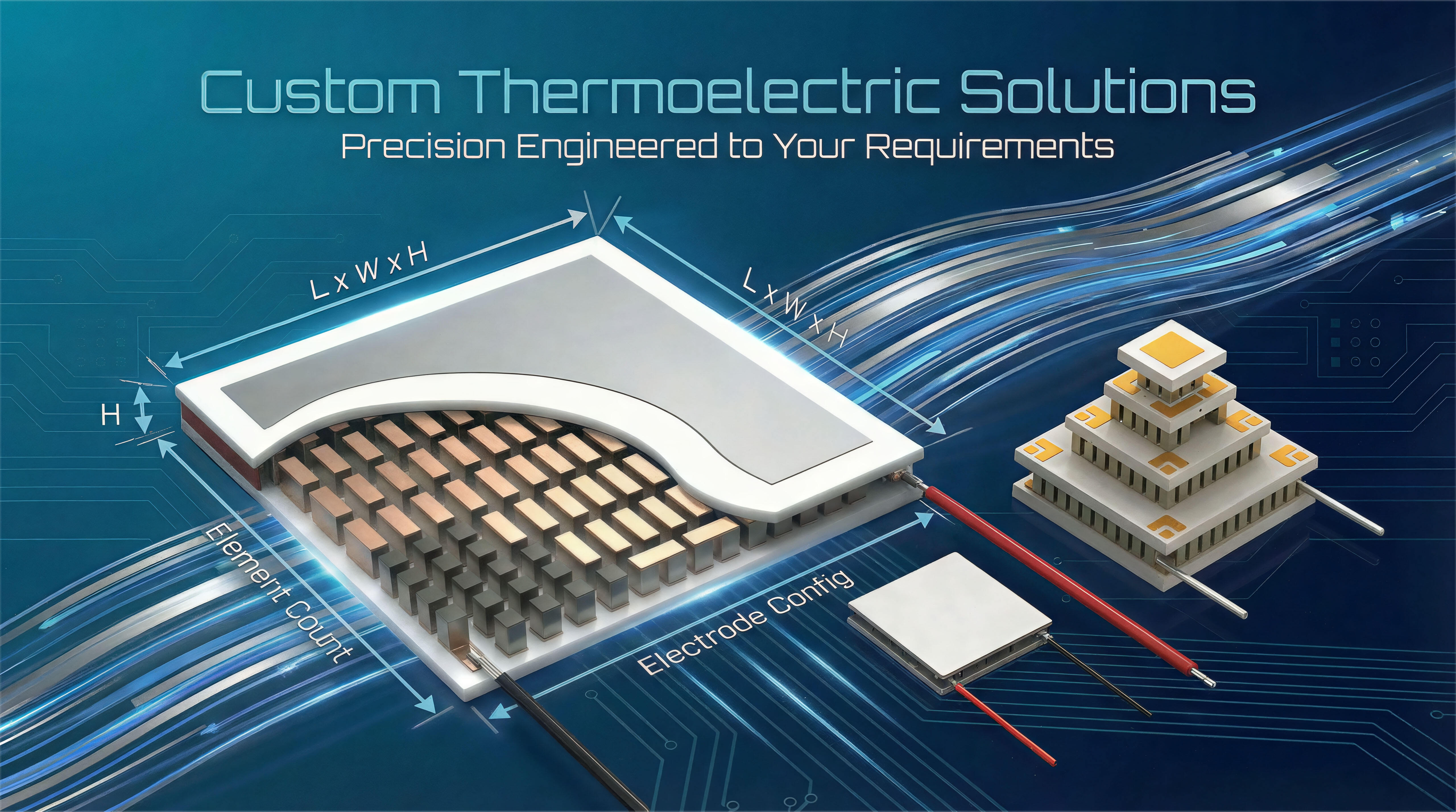

With nearly two decades of thermoelectric industry experience, our cross-functional engineering team specializes in solving complex thermal challenges in demanding applications. By integrating thermal, mechanical, and electrical design expertise, we develop optimized thermoelectric solutions tailored to your specific temperature control requirements—even in space- and power-constrained environments.

All customization is performed fully in-house, from thermoelectric module design to integrated cooling assemblies, allowing tight control over design intent and manufacturing quality.

Based on defined requirements, we typically provide a technical proposal within 1–3 working days, followed by prototype delivery in 2–4 weeks, depending on design complexity.

There is no minimum order quantity, enabling early-stage evaluation, pilot builds, and design verification prior to volume production.

An onsite reliability laboratory supports design verification and qualification testing. We conduct mechanical, environmental, and operational tests, including vibration, shock, shear strength, temperature cycling, thermal shock, high-temperature storage, and vacuum operation.

Testing capabilities align with Telcordia GR-468 CORE and MIL-STD-883, providing objective data to support design validation and ensuring long-term performance and reliability before mass production.

Our high-performance thermoelectric coolers enable next-generation stability chambers to achieve unparalleled temperature and humidity control. Our custom-designed Peltier modules form the heart of these critical systems, delivering the precise cooling power (up to 223W/unit) and tight temperature stability (±0.1°C) required for pharmaceutical testing and material conditioning applications. Unlike conventional compressor systems, our solid-state TECs provide vibration-free operation and lower noise performance (<50dB) - essential for sensitive measurement environments. The moisture-resistant construction prevents internal condensation while our patented heat dissipation design maximizes energy efficiency (40% savings at 25°C setpoints). With 20+ years of experience in thermoelectric engineering, we partner with chamber manufacturers to optimize: thermal interface design, power management, and control system integration - ensuring reliable, maintenance-free operation throughout the product lifecycle.

Key Contributions to Chamber Performance:

• Enables compact system architecture (30% space savings vs compressor designs)

• Delivers faster temperature recovery after door openings

• Supports precise humidity control through stable thermal baselining

• Eliminates refrigerant requirements for sustainable operation