P&N and i-TEC work closely with customers to develop optimized TEC designs for unique thermal challenges

Inspired by the ancient Chinese philosophy of "Teaching Students According to Their Aptitude, P&N and i-TEC offers thermoelectric solutions ranging from precision tweaks to fully bespoke designs:

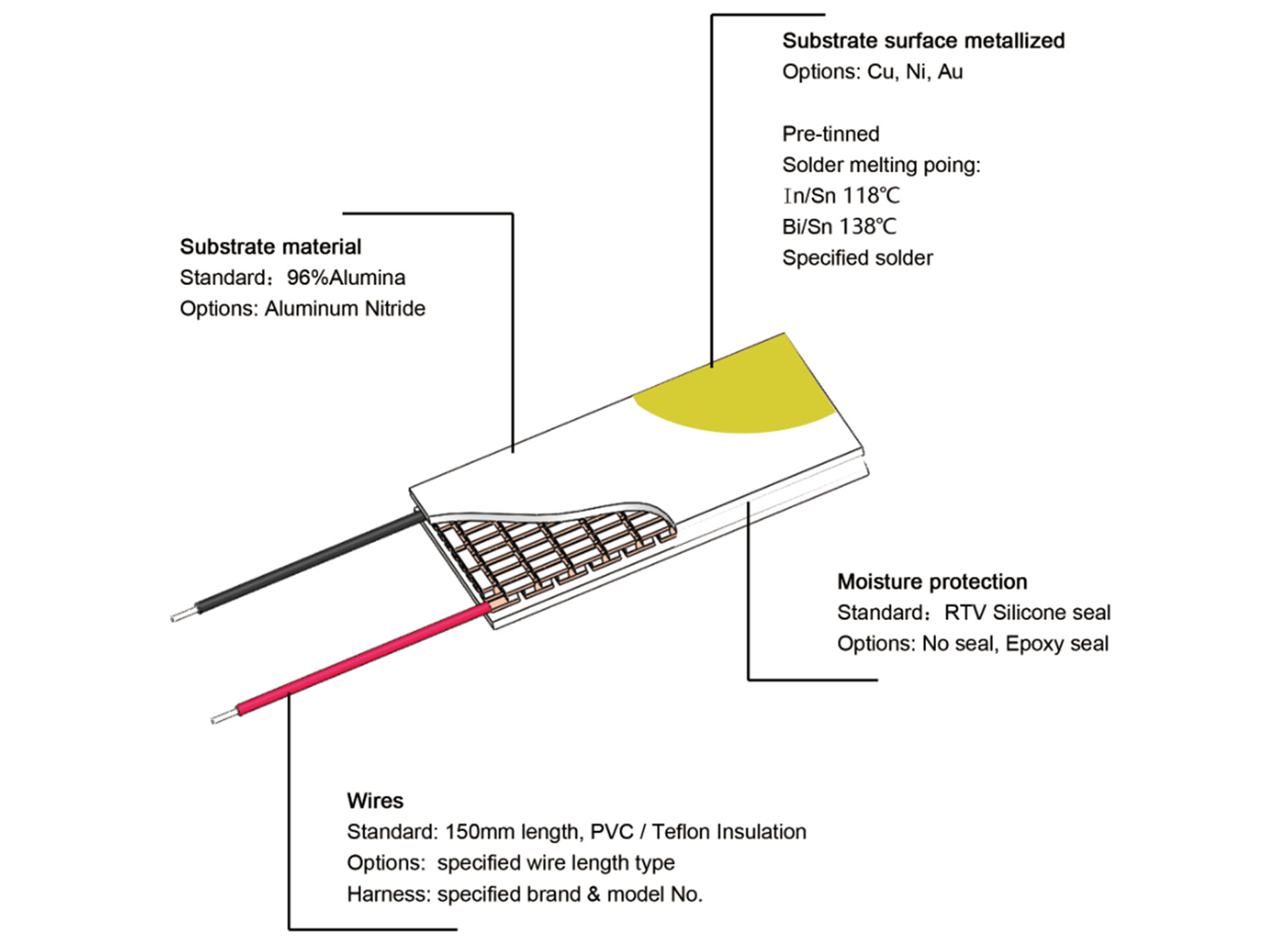

Custom modifications to standard modules

Full-parameter customization

Shape freedom: Beyond standard shapes to your unique geometry

Material selection: Al₂O₃/AlN substrates or specialty materials

Metallization: Custom electrode patterns & surface treatments

Miniature & Multi stage TEC module's customization

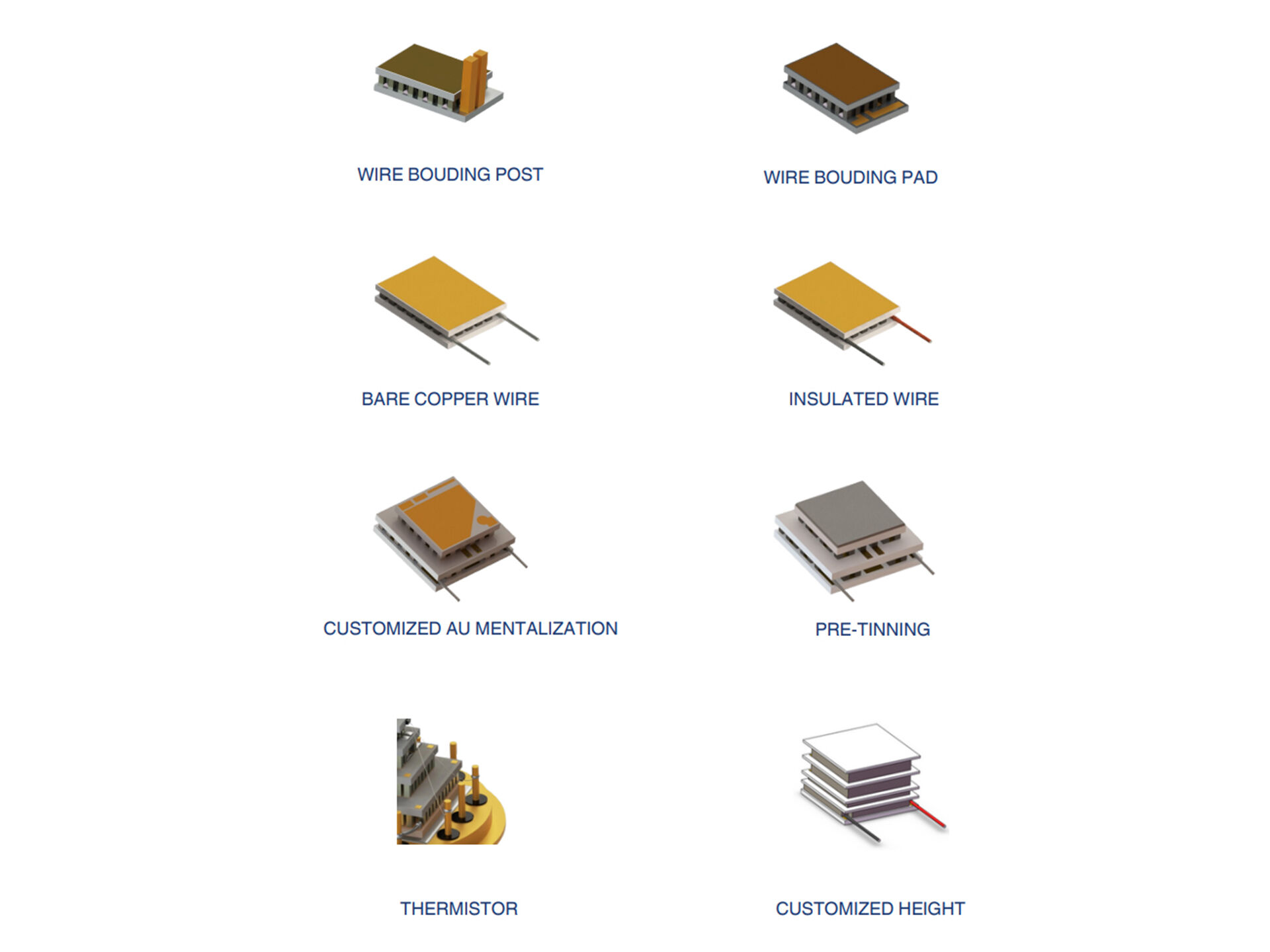

Wire connection: wire bouding post, wire bouding pad, bare copper wire, insulate wire, pre-tinning

Substrate surface metallized: CU, Ni, Au

Built-in thermistor: specified brand & model No

Customization Workflow:

Requirements → Thermal simulation → Prototyping → Rigorous testing → Volume production

(Supporting everything from single prototypes to mass production)