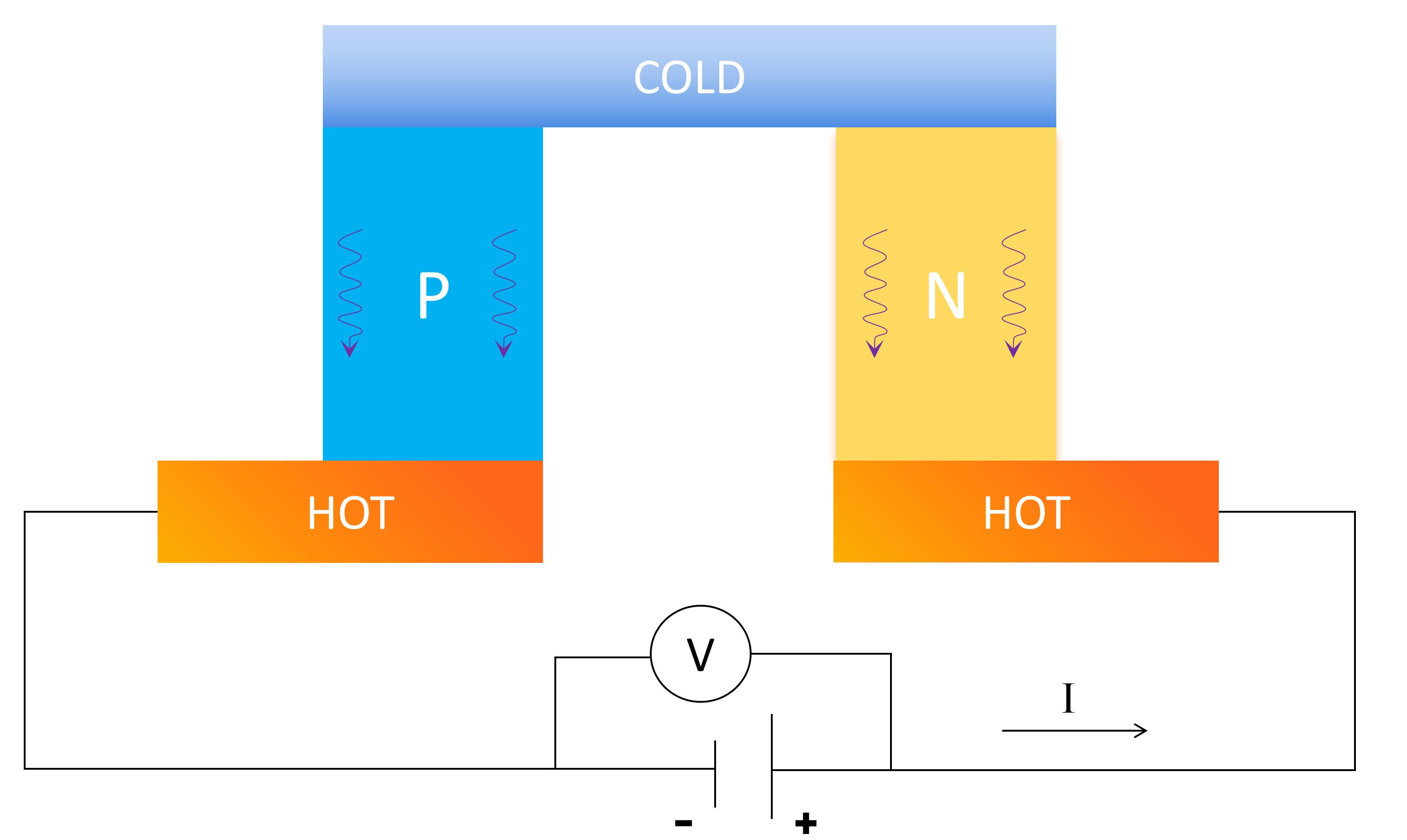

Infrared detector performance is fundamentally limited by thermal noise at ele-vated temperatures.

By lowering and stabilizing the detector operating temperature,TEC cooling leads to:

1.Reduced dark current and noise floor.

2.Improved NETD and image contrast.

3.Higher signal-to-noise ratio(SNR).

4.More stable and repeatable detector behavior over time.

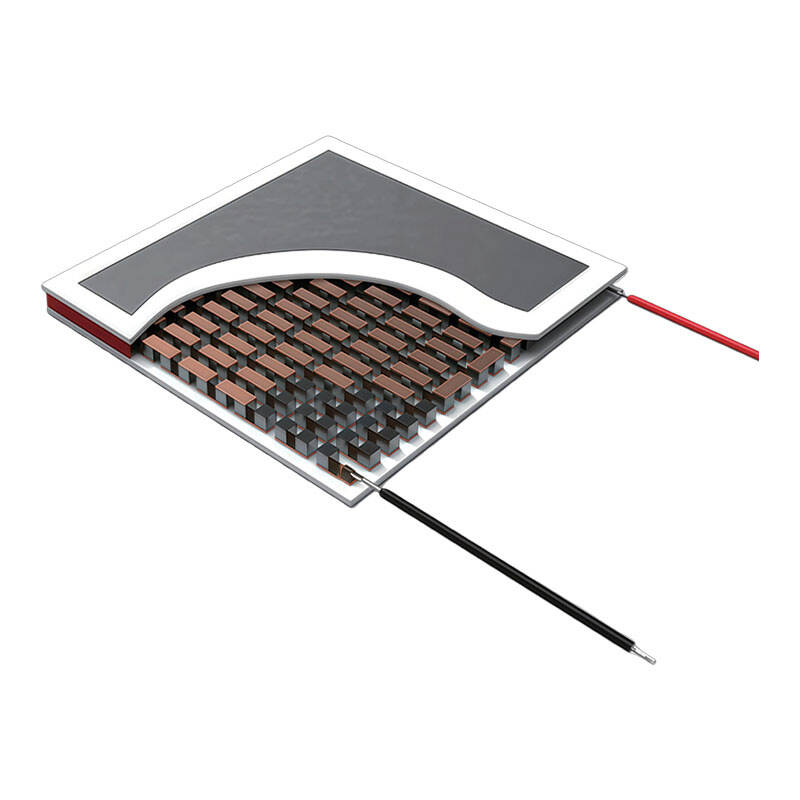

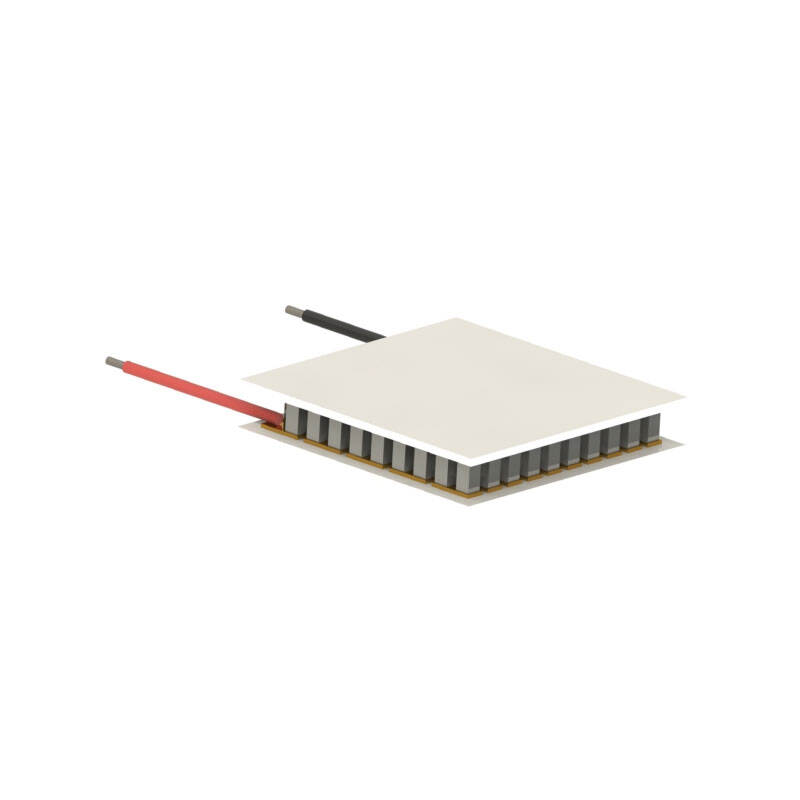

1.Solid-state design with no moving parts→long-term reliability

2.Zero vibration operation→no impact on imaging stability

3.Precise temperature control(±0.1 K typical)→consistent detector performance

4.Compact and orientation-independent→easy system integration

5.Fast thermal response→quick stabilization after power-on

1.Long-range infrared imaging and surveillance systems.

2.Scientific and analytical instruments.

3.Medical and life-science thermal imaging systems.

4.Industrial inspection and monitoring systems.

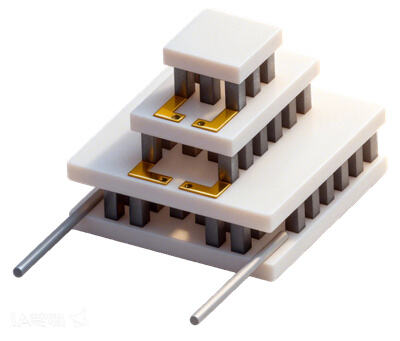

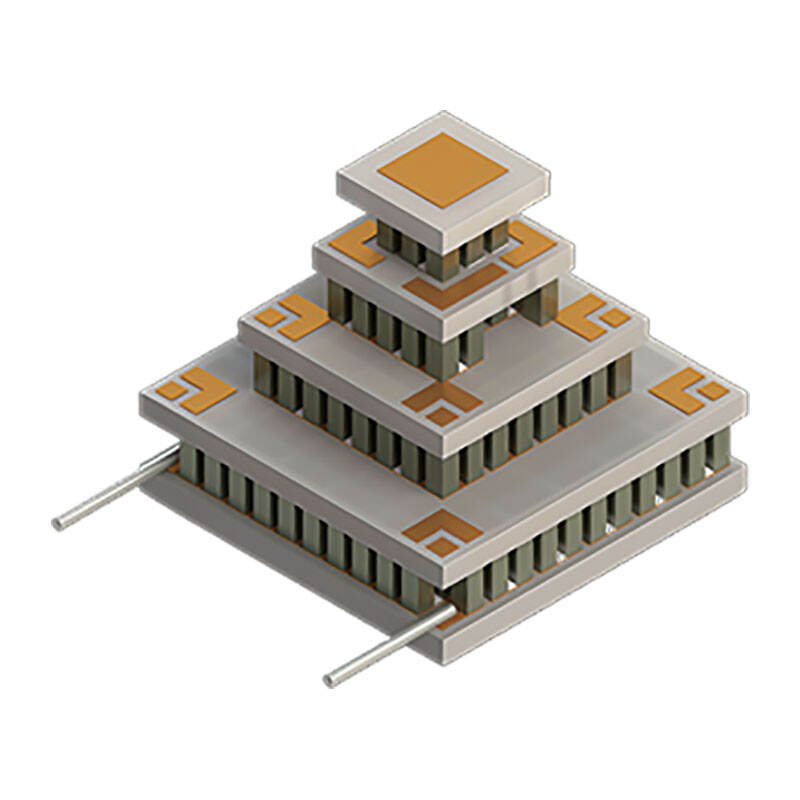

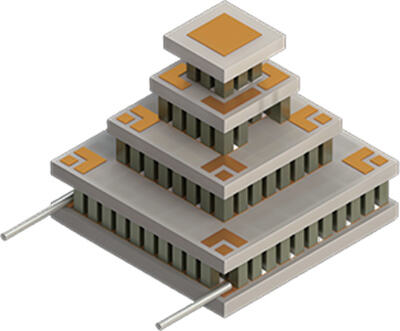

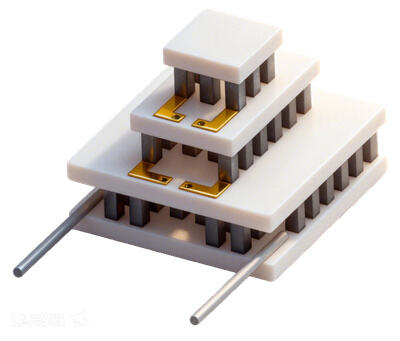

The following models represent typical multi-stage TEC models commonly used in infrared detector applications.They are provided for reference and comparison only,not as a complete product list.

| TEC model | Imax(A) | dTmax(®C) | Qcmax(W) | Umax(V) | ACR(ohm) | Top(mm) | Bottom(mm) | Height(mm) |

| 4ITEC-116- 040210 | 0.5 | 128 | 0.28 | 7.53 | 14.5 | 2.6x2.6 | 7.4x7.4 | 6.9 |

| Th=30℃& Vacuu m | ||||||||

| TEC model | Imax(A) | dTmax(°C) | Qcmax(W) | Umax(V) | ACR(ohm) | Top(mm) | Bottom(mm) | Height(mm) |

| 3iTEC-044- 040410 | 0.57 | 115 | 0.28 | 3.4 | 5.65 | 2.4x2.4 | 6.4x6.4 | 5.3 |

| Th=30°℃& Vacuum | ||||||||

| TEC model | Imax(A) | dTmax(C) | Qcmax(W) | Umax(V) | ACR(ohm) | Top(mm) | Bottom(mm) | Height(mm) |

| 3iTEC-071- 040210 | 0.55 | 115 | 0.4 | 5.8 | 9.05 | 2.6x2.6 | 6.2x6.2 | 5.3 |

| Th=30℃& Vacuum | ||||||||