- Overview

- Key Features

- Applications

- Specifications

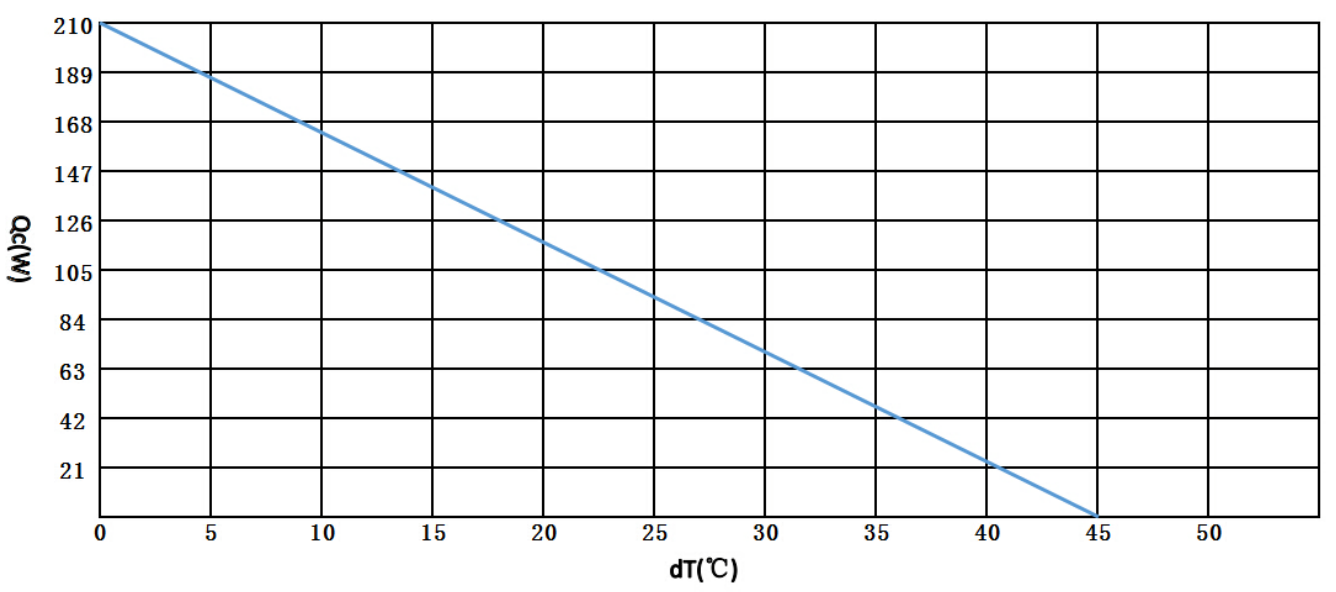

- Performance curves

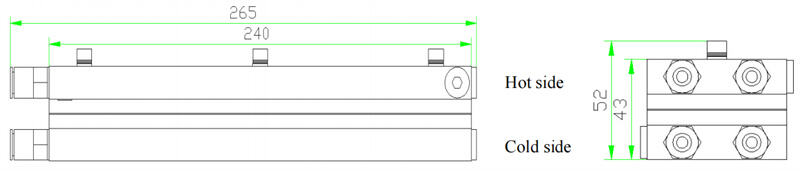

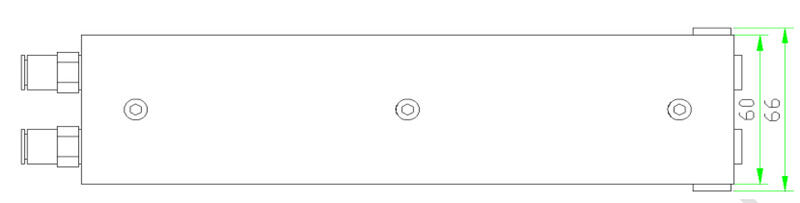

- Mechanical Drawing

- Custom Options

- Recommended Products

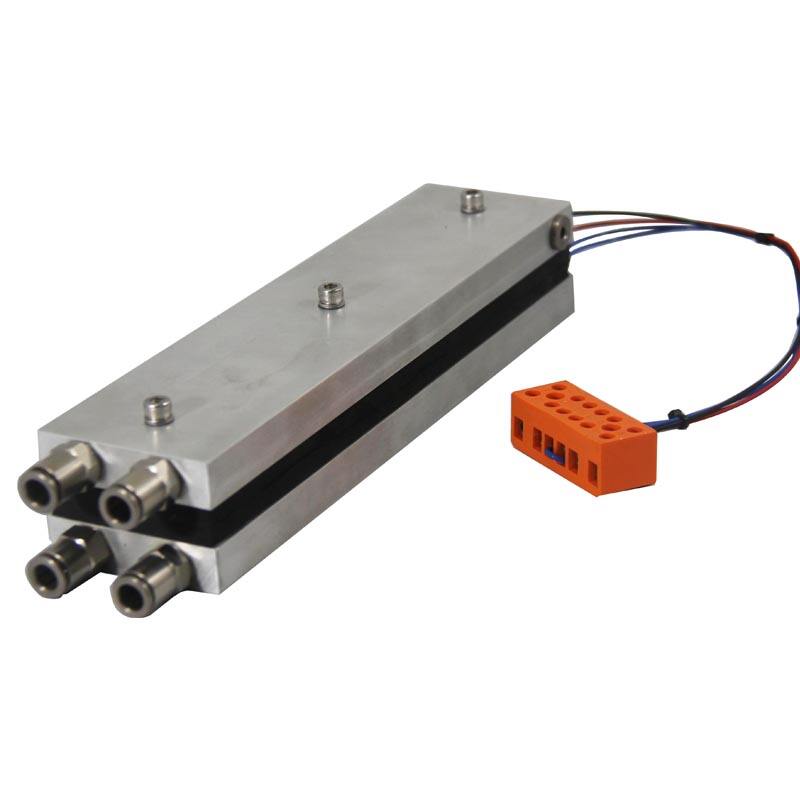

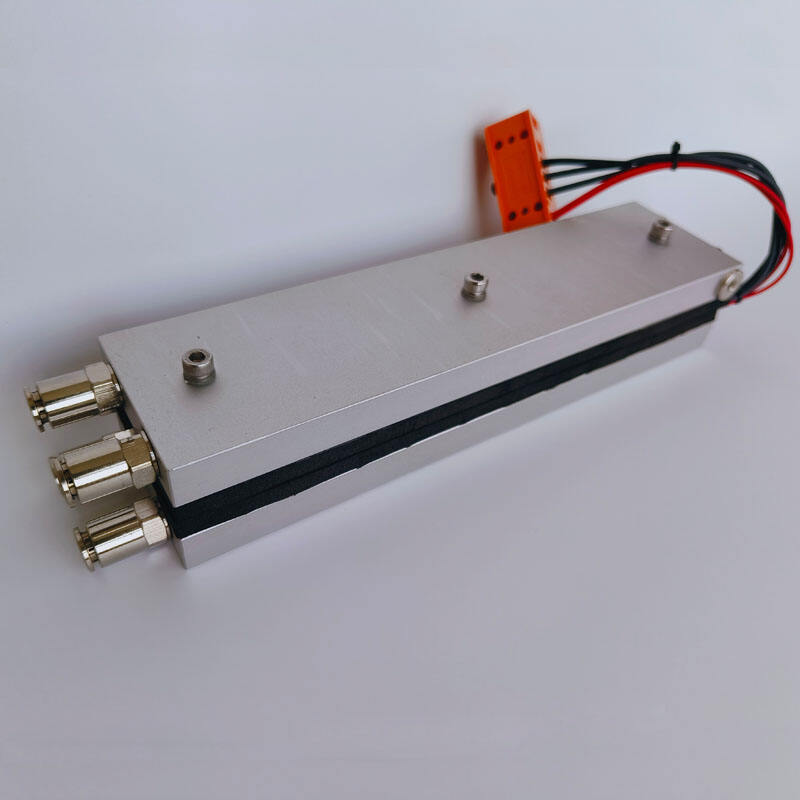

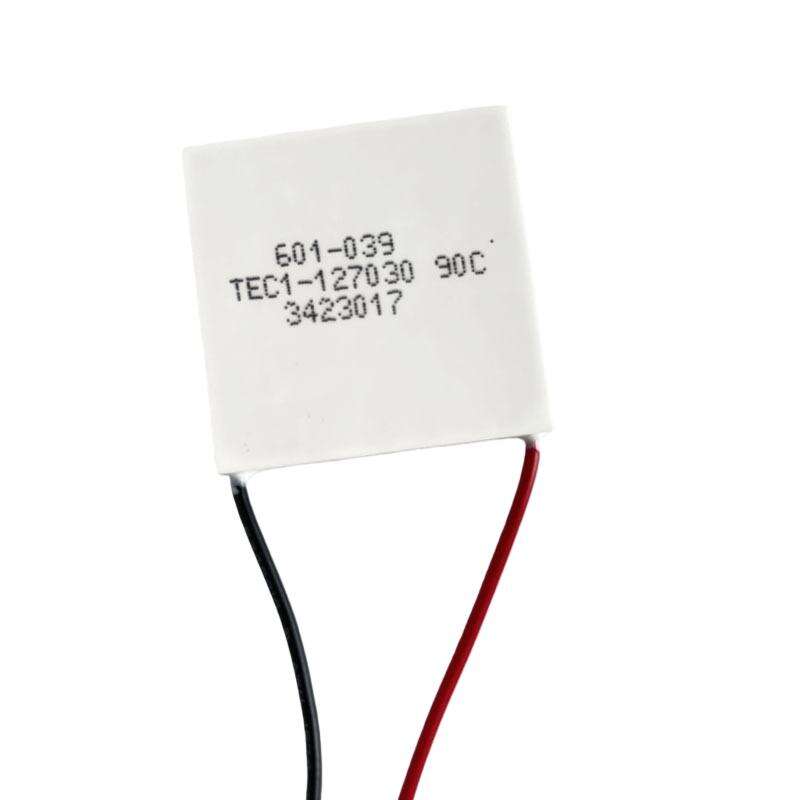

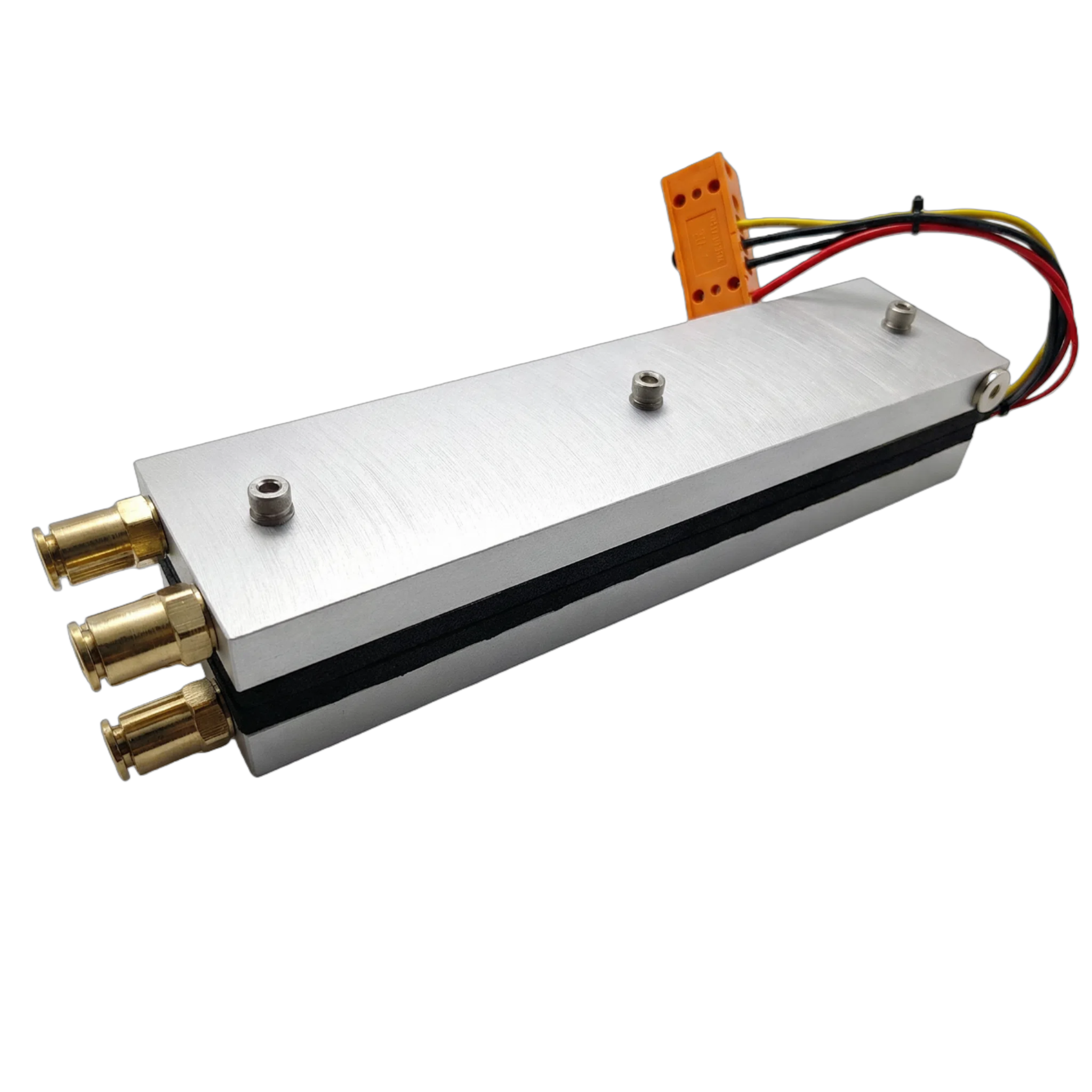

The P&N Technology’s LL-210-24 thermoelectric liquid cooler assembly delivers reliable, space-efficient cooling by transferring heat between two liquid heat exchangers. One exchanger absorbs heat from the target object, while the other dissipates it, ensuring effective thermal management. Custom-designed thermoelectric modules maximize the coefficient of performance (COP), reducing power consumption without compromising efficiency.

With a maximum cooling capacity (Q<sub>c</sub>) of 210W at ΔT = 0°C and a maximum temperature differential (ΔT) of 45°C at Q<sub>c</sub> = 0, the system balances high-performance cooling with robust thermal control. The integrated liquid heat exchangers support distilled water with glycol for versatile operation.

Operating at 24V DC (8.1A), the unit features bidirectional current control, allowing seamless switching between cooling and heating modes to adapt to dynamic requirements. Compact, energy-efficient, and engineered for precision, the LL-210-24 is ideal for applications demanding stable temperature regulation.

Key Features

Compatible with water/glycol mixtures

Precise temperature control

Reliable solid-state operation

High efficiency

Applications

• Medical Lasers

• Industrial Lasers

• Medical Diagnostics

• Analytical Instrumentation

Specifications

|

Max Cooling Power(W) |

210 |

|

Running Current (A) |

8.1 |

|

Nominal Input Voltage (V) |

24 |

|

Max Input Voltage (V) |

27 |

|

Power Input (W) |

194 |

|

Operating Temperature(℃) |

-10 to 85 |

|

Weight (kg) |

1.4 |

|

MTBF(fans-hrs) |

100,000 |

|

Performance Tolerance |

±10% |

Performance curves

Mechanical Drawing

Custom Options

Wire length: specified wire length.

Harness: specified brand & model No.

Connector size: specified.

Liquid block material: standard anodized aluminium, SS304/316 optional.