Thermoelectric coolers are specialized devices that serve to keep things chilled. They are worldwide and everywhere under sensors, in particular. Sensors have to work well, and if they get too hot, they may not. Which is where thermoelectric coolers like this come in. These coolers use electricity to ferry away heat from the sensors, ensuring they stay at the appropriate temperature. This is super important because when sensors are at the correct temperature, they provide accurate readings and last longer. At my company, PN, we are committed to producing high quality thermoelectric coolers that will enhance sensors.

Thermoelectric Cooling - What You Need to Know for Thermal Management Success

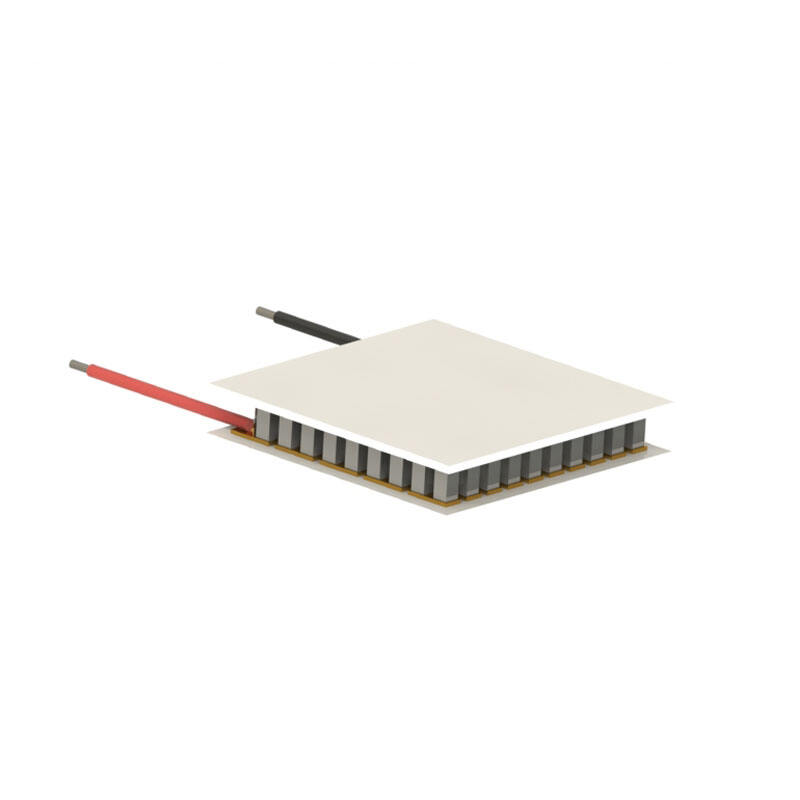

It’s pretty neat being able to control temperature without using moving parts and that’s where thermoelectric cooling can help. It operates on the Peltier effect, so it cools when arranged one way and heats when reversed. That’s good for sensors, which often do require cooling to function as they should. Sensors that run too hot may provide false readings, or worse still, break. This problem can be solved in part by using thermoelectric coolers.

The coolers are built using two kinds of materials, known as n-type and p-type semiconductors. That’s because when electricity is sailed through their materials, the cold side gets cooler and the hot side heats up. This temperature disparity is the mechanism used to keep sensors cool. For instance, on an outdoor temperature sensor, a thermoelectric cooler arrangement might prevent the sensor from overheating in the sun, so that it reads the temperature accurately.

Thermoelectric coolers are small and can be easily integrated into various devices. That’s a feature that could be handy for portable sensors like the ones used in medical devices or handheld gizmos. They are also quiet, with no moving parts, so they should last forever on a minimum of maintenance. Our company PN specializes in fabrication of efficient and reliable thermoelectric coolers for variety of sensors. We are well aware that details count big, we take them very seriously; we let our products speak for themselves.

Thermoelectric Coolers Can Help To Lower Sensor Failure Rates

One of the biggest challenges with sensors is that they can break if they get too hot. This can lead to all sorts of problems, not excluding sensitive applications like medical monitoring or environmental sensing. These failure rates can be lowered with the use of thermoelectric coolers, which keep sensors a stable temperature. Keeping sensors cool helps them work more efficiently and reduces the chance they will break.

In industrial plants, sensors keep an eye on equipment. A sensor that overheats could fail, resulting in equipment issues. By using thermoelectric coolers, we can maintain those sensors within a safe temperature range, so they continue to function the way they are supposed to. This not only helps them avoid failures but also saves money since the companies don’t need to swap broken sensors as frequently.

In addition, thermoelectric coolers can enhance the precision of sensor devices. When the sensors are within that range, they perform accurate readings. For instance, in a weather station, to provide reliable forecast temperature measurements are vital. If the sensor is too hot, it may indicate a temperature as higher than it really is. This could generate incorrect weather forecasts. PN's thermoelectric coolers keep sensors cool and reliable.

heat loads, sensors are important devices and thermoelectric coolers plays huge role for the thermal management of them. They help minimize damage and improve the operation of sensors. Swapping out your sensor for PN's thermoelectric coolers can rest assure your sensors operate consistently and last much longer Reliable for any task.

Where to Get Thermoelectric Cooler for Sensors You Can Trust

If you’re in the market for a thermoelectric cooler for your sensor, it’s critical to look that wherever you purchase from has good quality products. A fantastic one would be to choose a firm similar to PN. They focus on thermoelectric cooling solutions that are effective for sensors. PN provides a large series of coolers to be installed on various sensors: small devices or big systems. With an authorized dealer such as PN, you can trust what you’re strapping on to your machine because it will be a durable product that isn’t going to break in once ride.

PN's products can be found online at their website. This means you'll have no issues searching thru their coolers to find the perfect product for your situation. They usually post informative descriptions of every product, how it works and benefits. If you have questions, PN also has customer support whom can assist you in figuring out what product is best For your sensor.

Oh, and you may see PN's products in some of those electronics stores down the street or at a trade show. That way, you can see the coolers in real life and ask questions about them. Before you purchase a thermoelectric cooler, always look for reviews and ratings from other people. This feedback can provide a good sense of whether a product is effective. A quality thermoelectric cooler is important to maintaining the correct temperature of your sensor, and PN is a great supplier to source it from.

Which Developments Are Really Pushing Thermoelectric Cooler Performance in Sensors?

It's been quite a journey for thermoelectric coolers, which are now the recipients of new technologies and designs. These enhancements contribute to making them more efficient, so they can better cool sensors and use less energy. Among the most significant advances are new materials used in the coolers. Some materials have been found to be more effective at conducting heat than others. Through the use of these new materials, companies like PN can produce thermoelectric coolers that will cool more rapidly and last longer.

More detailed innovation are coolers themselves. The coolers remain a big challenge: Engineers are always trying to figure out ways of making them smaller, and more efficient. That means even small sensors could have effective cooling systems without it coming at too high of a physical space cost. For instance, some coolers are now designed to be very small and fit in tight areas that no other cooler would go.

Furthermore, intelligent technology is making its presence known with enhanced thermoelectric coolers. Nowadays, many new coolers are able to modulate the power of their cooling according to the detected sensor temperature. That means they consume only as much energy as required, which is more environmentally friendly and less expensive for your electric bill. PN is at the forefront producing these smart coolers that do their job in an energy-efficient manner. The he results are helping thermoelectric coolers and chillers to be more effective at controlling the temperature of sensors, meaning they can operate correctly and reliably.

Maximizing Heat Transfer in Sensors Using Thermoelectric Coolers

Thermoelectric Coolers For Your Best Sensor Performance - The basis for good sensor performance is a well adjusted thermal management on the sensors. The first step is to select the appropriate cooler for your sensor. Look at how the sensor operates and also look at the cooler. Companies like PN can advise on which products work best for various sensors. This is important, as the proper fit of the sensor will contribute to a good cooling performance and in turn make sure that your sensor won’t overheat.

Secondly, the correct installation is crucial for efficient thermal control. Ensure the thermoelectric cooling system is oriented properly to provide maximum cooling. Refer the guide installed in src/pn or latest to see how you can make it work. look at how the cooler fits in for sensor, make sure there is no openings. The cooler-sensor interface is in good thermal contact to minimize the heat interfacial resistance.

It’s also useful to check on the thermoelectric cooler from time to time. Verify the temperature readings and that everything is functioning as expected. If the cooler is not maintaining the sensor at proper temperature, troubleshoot. This could mean the need to troubleshoot power supply issues, or keeping an eye out for any obstructions that hinder cooling.

Finally, you can use more than one thermoelectric cooler to cool larger and/or complex sensor systems. This can serve to equalize the cooling power for all the sensors. With these simple steps and relying on tried-and-true PN products, you can keep your sensors in the black working better and lasting longer as a result. Having good heat management is crucial to use your sensors correctly, and thermoelectric coolers can be the answer.

Table of Contents

- Thermoelectric Cooling - What You Need to Know for Thermal Management Success

- Thermoelectric Coolers Can Help To Lower Sensor Failure Rates

- Where to Get Thermoelectric Cooler for Sensors You Can Trust

- Which Developments Are Really Pushing Thermoelectric Cooler Performance in Sensors?

- Maximizing Heat Transfer in Sensors Using Thermoelectric Coolers